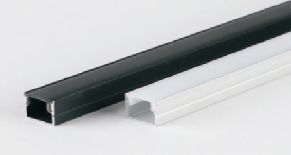

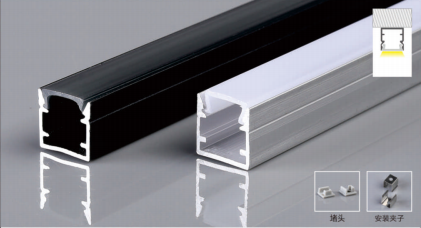

aluminum moulding profiles

Aluminum moulding profiles represent a cornerstone of modern construction and manufacturing, offering versatile structural solutions across numerous industries. These precision-engineered components are manufactured through advanced extrusion processes, where heated aluminum billets are forced through specially designed dies to create consistent cross-sectional shapes. The resulting aluminum moulding profiles maintain uniform dimensions and superior surface finish, making them ideal for applications requiring both structural integrity and aesthetic appeal. The main functions of aluminum moulding profiles encompass structural support, decorative finishing, protective barriers, and framework construction. Their lightweight nature combined with exceptional strength-to-weight ratios makes them particularly valuable in automotive, aerospace, and architectural applications. Technological features include corrosion resistance through natural oxide layer formation, excellent thermal conductivity, and remarkable malleability that allows for complex geometric configurations. The extrusion process enables manufacturers to create intricate internal chambers, cooling channels, and mounting grooves within single profiles, eliminating the need for additional machining operations. Surface treatments such as anodizing, powder coating, and mill finishing enhance both durability and visual characteristics. Applications span from window frames and curtain walls in commercial buildings to heat sinks in electronic devices, automotive trim components, and industrial machinery frameworks. The modular nature of aluminum moulding profiles facilitates rapid assembly and disassembly, making them popular in temporary structures, exhibition displays, and modular construction systems. Advanced alloy compositions provide specific mechanical properties tailored to particular applications, with 6061 and 6063 alloys being most commonly used for general-purpose aluminum moulding profiles. The precision tolerances achievable through modern extrusion technology ensure consistent fit and finish across large production runs, reducing assembly time and material waste.